|

|

GN Introduces a New Paradigm for SPM, Nano Manipulation, Nano electrical and chemical Probing and Nanomachining the nanotool™ V series of active Cantilevers, with Diamond and Conductive Diamond Tips

Featuring

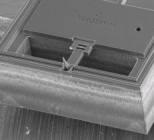

Specific styles will be sampled at introductory prices to qualified companies and researchers. Contact nanotool@gennano.com , nanotool™ V is protected by trademark, copyright and patent applications all rights are reserved to General Nanotechnology LLC 2002. The basic nanotool™ V series consists of a Digital Instruments* footprint MEMS cantilever platform capable of many new functions and features. These features include the ladder like structure down the middle of the part. The ladder is a thermal force generator and drives the two long arms which go up the sides of the part to clamp the tip platform and immobilize or provide higher spring constant to the mechanical action of the tip and primary cantilever. Additionally, the arms themselves may be covered by special silicon covers to form sealed continuous channels (see below bottom row right). These channels are fed from two large cavities under the main body by gas, vacuum or fluid. Furthermore a series of secondary cantilevers as can be seen just underneath the tip assembly (on the right upper row below) provide precise spring constant change as the primary cantilever is moved back and into them a micron or more. Many other new features are incorporated into the design and may be announced in the coming year as they reach production readiness.

*Digital Instruments is a trade name of Veeco

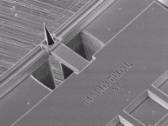

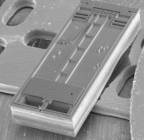

The back of the nanotool™ V series reveals the Dual Fluid or Gas chambers feeding the upper channel arms arranged around the tip platform. In this example the part has relatively weak secondary cantilever arms arranged just behind the tip platform to provide increased spring tension for conductive probing of subject materials.

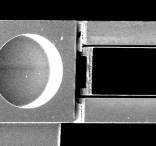

Nanotool™ V series are also available without any rear obstructions, beams or secondary cantilevers but in which the action of the clamping channel arms serves by design to make the appropriate spring constant change in the tip platform behavior. Inquire at GN to see if the special needs of your application can be supported by the nanotool™ Series of active cantilevers! The nanotool™ Vseries includes specialty primary cantilevers such as the Kelvin Probe cantilever below designed to operate in a SXM class high performance AFM with a conductive nanomachining capable tip in full support of GN's own AFM Guided Nanomachining. Note that this part is also an example of a secondary beam Z stop. The continuous 450 micron thick bar or beam which extends behind the cantilever and exactly 1.5 microns below the tip acts to provide ultimate rigidity for nanomachining operations in obdurate material such as Titanium Nitride and Diamond.

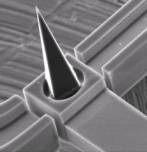

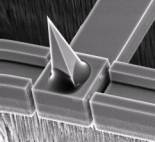

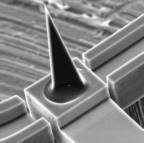

Nanotool™ V Conductive or Standard Diamond tips (as below) meet or exceed the highest standards for tip sharpness and durability in research and industry!

|

ABOUT | PROBE 3D | SMARTFOCUS | GALLERY | DEMO | CONTACT | HOME COPYRIGHT

2001 GENERAL NANOTECHNOLOGY. LLC. ALL RIGHTS RESERVED. |